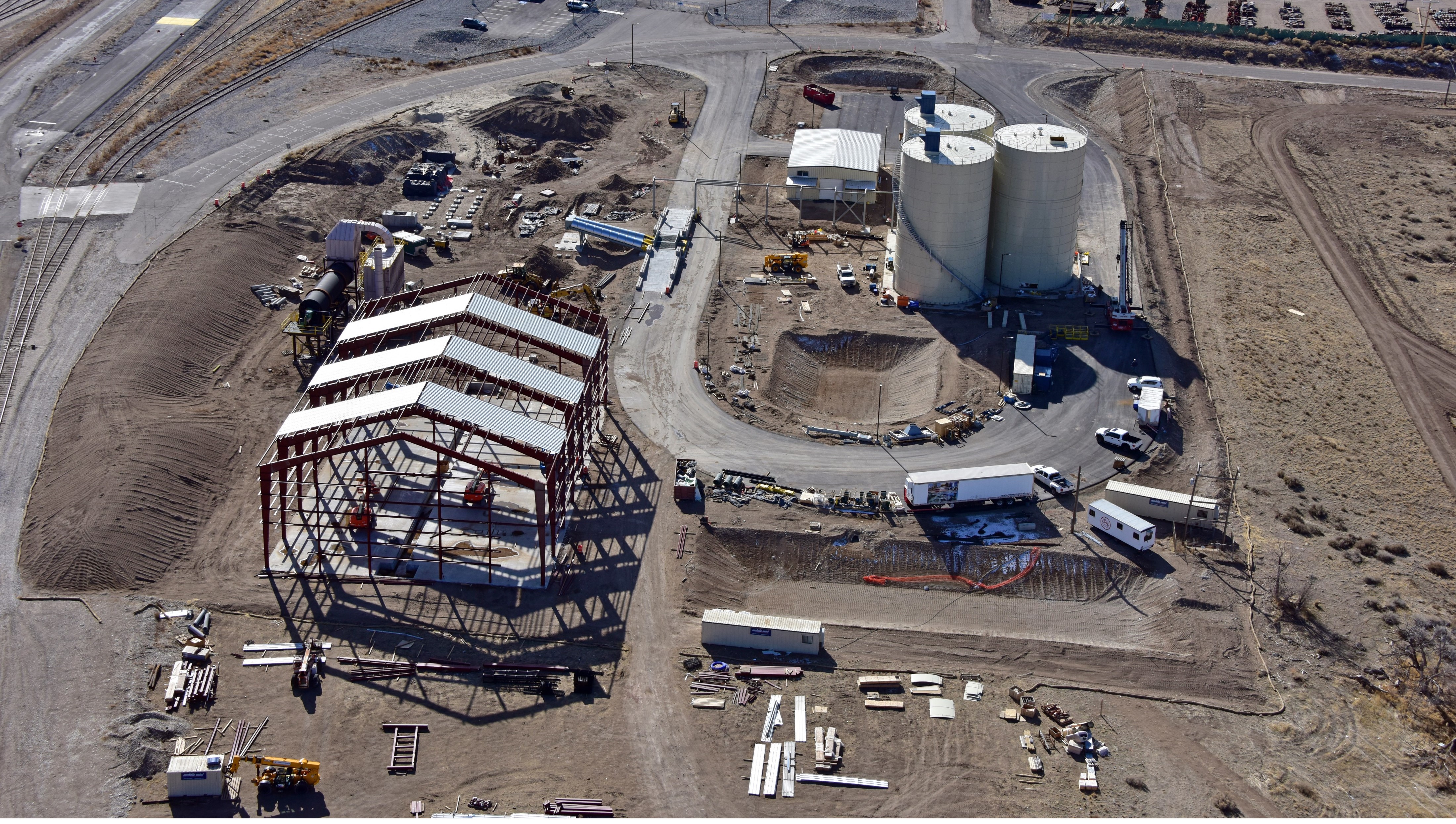

The plant receives raw pozzolan by truck, has a 15,000 square foot storage building, a rotary dryer, belt conveyor systems, a Cemengal Plug & Grind ball mill system, pneumatic conveyance systems, three storage silos for finished product and truck loadout systems.

Finished product is loaded out into pneumatic bulk trucks for transport to customers. The loadout system is designed to load out typical 40-ton double trailers in less than 15 minutes.

All aspects of the plant are operated from the central control room. The plant also features a Quality Control laboratory, offices, and maintenance facilities.